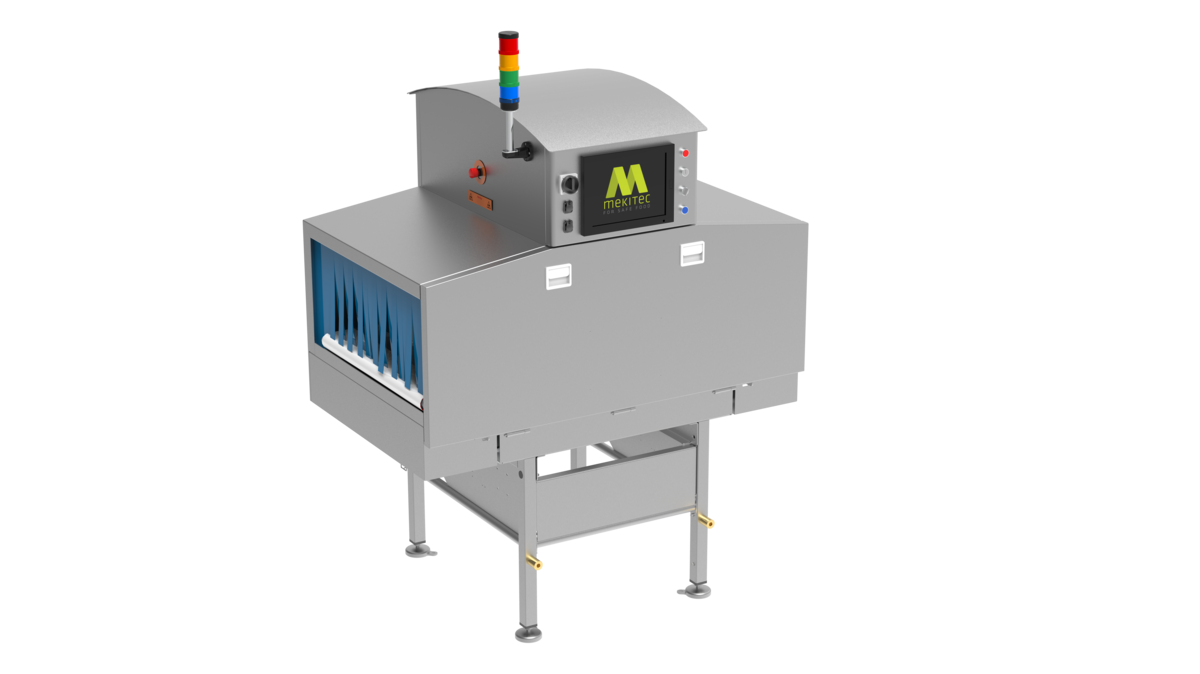

BIGMEKI

X-Ray Inspection System for Large Products

X-Ray Inspection System for Large Products

X-ray technology has become the go-to option for food safety, but with Mekitec's inspection solutions you won't have to compromise the quality and traceability of your production either. Give you and your customers a peace of mind by choosing Mekitec.

BIGMEKI quality control system leverages the latest X-ray image processing technology and artificial intelligence algorithms. This system combines the strengths of MIDMEKI system with substantially larger detection area, making it ideal for inspecting larger packages, including secondary packaging and oversized primary packages.

Specifically designed for the inspection of large-scale products, BIGMEKI rises to the challenge of maintaining quality control for sizable items. Like all Mekitec X-ray systems, it effortlessly handles high moisture content, elevated salt levels, and a variety of packaging materials (including metal and aluminum) without compromising inspection accuracy.

The BIGMEKI focuses on the essential features that matter most to food producers dealing with larger packages. By expanding our inspection capabilities to accommodate bigger items, we continue to deliver unparalleled performance and value to our most important stakeholder - our customer.

Technical Specifications

| Conveyor Speed | Option 1: 0.23-0.44 m/s Option 2: 0.14-0.22 m/s |

| Conveyor Load Capacity | Option 1: max. 30 kg Option 2: max. 60 kg |

| X-ray Power | 40-150 kV, 1-10 mA, max 500 W |

| X-ray Leakage | Less than 1 µSv/h |

| Detector | Linear scanner, resolution 0.4mm |

| Software | Mekitec X-Ray Inspection System SW |

| Operating System | Windows 11 |

| Connectivity | USB, Ethernet |

| HMI | 15" Color TFT LCD Screen |

| Operation Temperature | 0-35°C ambient |

| Cooling | Optional cooling system¹ |

| IP Rating | IP65² |

| Relative Humidity | 30-85%, non-condensing |

| System Power Supply | 110/240 VAC, 50-60 Hz |

| Dimensions (W x D x H) | 1600 mm x 1100/1373 mm x 2205 mm |

| Weight | 700 kg |

| Material | Stainless steel, brushed |

| System Conveyor | EU and FDA food use approved conveyor belt |

| Radiation Protection | EN 61010-02-091, FDA CFR 21 part 1020, 40 |

| Safety System | Safety circuit CAT 3, Performance Level PL d |

² Requires the use of washing covers for air intake.

Detection Area

Maximum detection area based on product height (mm)

Maximum product length will be defined by the selected rejection box and product features.

Maximum product length is 600 mm. For longer products, contact Mekitec.

Product Applications

BIGMEKI is especially suitable for the inspection of:

- Large packaged products

- Secondary packaging

- Oversized primary packages

- Trays with several products

- Large-scale food items

Mekitec Oy, info@mekitec.com, www.mekitec.com

Disclaimer: All information is provided for information purposes only and shall not be considered as assured characteristics. The information and technical data presented in this document are subject to change. Customers should obtain and verify the latest relevant information before placing orders. If you have any questions related to the datasheet, please contact us via email or phone. Thank you.

Copyright 2024 Mekitec Ltd. All rights reserved.

Key Features

AI-Powered Technology

Latest X-ray image processing technology with artificial intelligence algorithms

Large Detection Area

Substantially larger detection area ideal for oversized primary and secondary packaging

Flexible Configuration

Two conveyor speed and load capacity options to match production requirements

Material Versatility

Handles high moisture, elevated salt levels, and various packaging materials including metal and aluminum