Counter & Filling Inspection

Ensure perfect piece count and filling consistency in every package

Perfect Count, Every Time

In food production, customers expect exactly what they pay for. Whether it's cookies in a package, pieces in a snack mix, or filling consistency across products, accurate counting and filling verification are critical for customer satisfaction and brand reputation.

Counter & Filling Inspection technology transforms your X-ray inspection system into a precision counting and filling verification solution that works even when pieces overlap or touch—a common challenge in packaged food products.

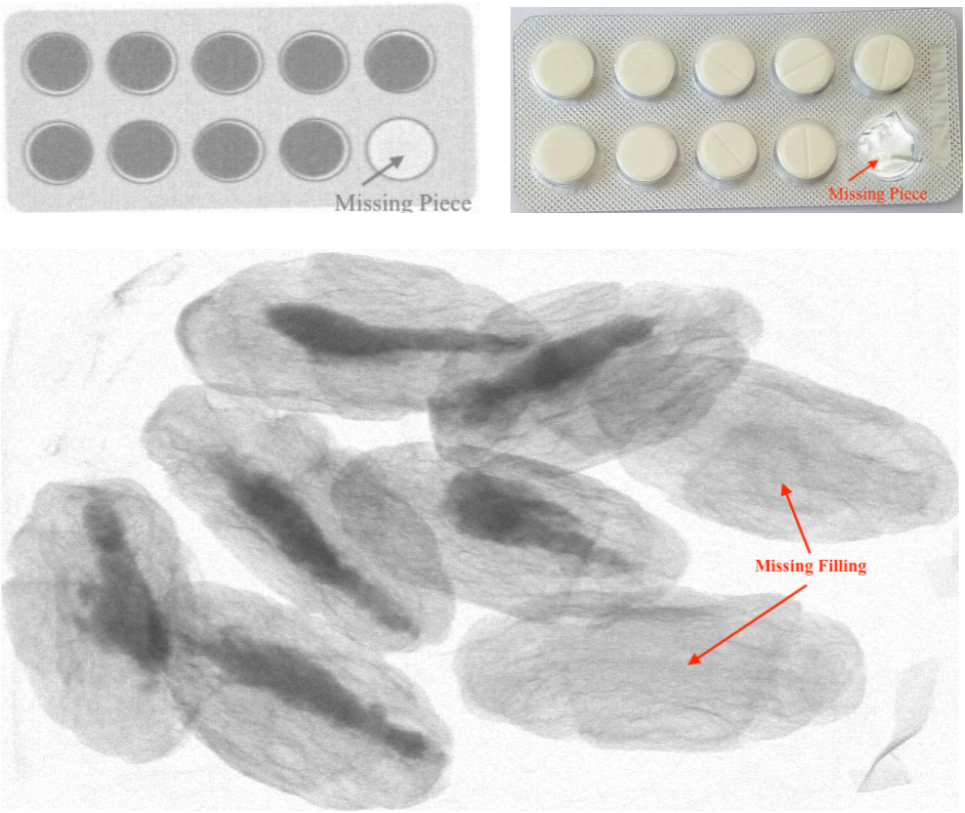

The Challenge of Overlapping Products

Traditional counting methods struggle when products overlap, stack, or touch each other within packaging. This leads to:

- Inaccurate counts that result in customer complaints

- Over-filling that increases production costs

- Under-filling that damages brand reputation

- Manual inspection requirements that slow production

Time-consuming visual checks with human error potential and production line slowdowns

Simple counting fails when pieces overlap or vary in size, leading to inaccurate results

AI-powered analysis accurately counts and verifies filling even with complex product arrangements

How It Works: Intelligence Behind Accuracy

Our Counter & Filling Inspection leverages cutting-edge artificial intelligence technologies, combining computer vision, machine learning, and deep learning algorithms to deliver unmatched counting and filling verification accuracy.

Advanced AI-Powered Analysis

The system employs sophisticated artificial intelligence to:

- Analyze product characteristics and identify individual pieces within complex arrangements

- Learn from production patterns to continuously improve counting accuracy

- Distinguish between valid products and defects with superior precision

Intelligent Recognition Technology

When pieces overlap, touch, or create challenging counting scenarios, our algorithms:

- Process complex visual information that traditional systems cannot handle

- Separate and identify individual items using advanced pattern recognition

- Maintain consistent accuracy across different product types and packaging conditions

- Deliver reliable results regardless of product orientation or arrangement complexity

Through continuous learning and adaptation, the system becomes more accurate over time, ensuring your quality standards are consistently met while reducing false rejections and operational costs.

Real-World Applications

Count cookies, crackers, and pastries accurately, even when they stack or overlap during packaging

Verify the right mix of different components and total piece count in variety snack packages

Integration Benefits

Counter & Filling Inspection works seamlessly with existing MEKI systems:

Enhanced by artificial intelligence algorithms for superior accuracy in complex counting scenarios

Complete traceability of count verification data for quality documentation and trend analysis

Quality Standards You Can Trust

Counter & Filling Inspection helps maintain:

- Consistent customer experience with accurate product counts

- Brand protection through reliable quality verification

- Cost control by eliminating both over and under-packing

- Regulatory compliance with documented counting verification

- Production efficiency through automated quality control

Investment That Pays for Itself

Consider the impact on a production line processing 100,000 units daily:

- Reduced customer complaints: 90% reduction in count-related issues

- Eliminated over-packing: $5,000-15,000 monthly savings in excess product

- Labor efficiency: Eliminates need for manual counting verification

- Brand protection: Maintains customer trust and loyalty

Ready to Ensure Perfect Counts?

Transform your quality control with Counter & Filling Inspection technology that guarantees every package contains exactly what your customers expect.

Contact Mekitec for a Consultation

Disclaimer: All information is provided for information purposes only and shall not be considered as assured characteristics. The information and technical data presented in this document are subject to change. Customers should obtain and verify the latest relevant information before placing orders.

Copyright 2026 Mekitec Ltd. All rights reserved

Key Features

Accurate Piece Counting

Precisely count individual pieces even when they overlap or touch within packaging

Filling Verification

Ensure consistent filling levels meet your quality standards across all products

Smart Separation Technology

Advanced algorithms separate touching pieces for accurate individual counting

Quality Consistency

Maintain brand trust by delivering the exact product count customers expect