MEKI Assurance Intelligence

AI-powered food inspection software that enhances detection accuracy while reducing waste

The Intelligence Behind Superior Food Safety Inspection

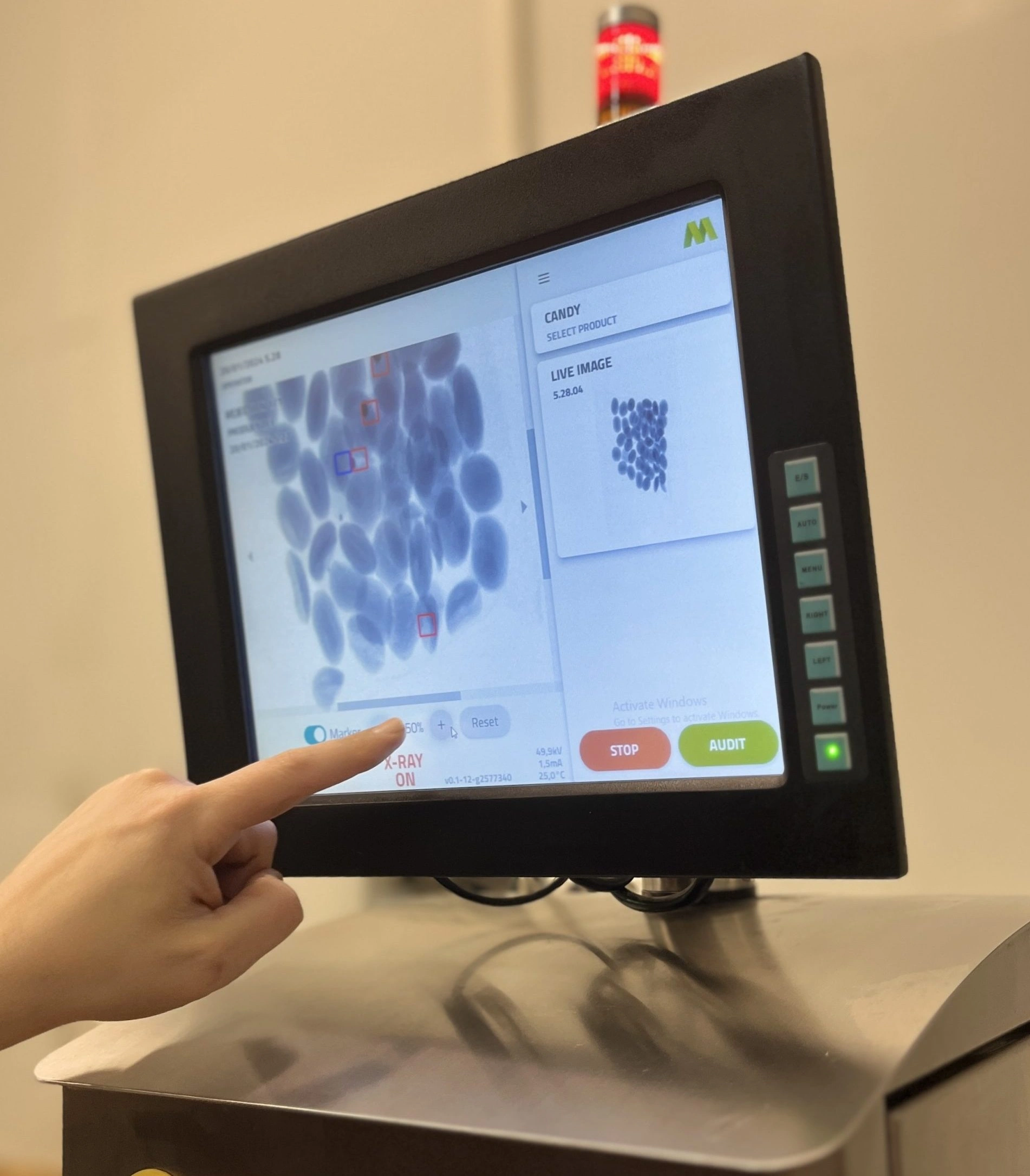

In modern food production, X-ray inspection is only as effective as the software interpreting the images. MEKI Assurance Intelligence transforms standard grayscale images into powerful food safety tools by detecting contaminants invisible to the human eye.

From Legacy to Leadership

Building upon Mekitec's proven inspection technology, MEKI Assurance Intelligence incorporates cutting-edge artificial intelligence algorithms that deliver:

- Superior detection of smaller contaminants

- Identification of lower-density foreign materials

- Significant reduction in false positive rejections

- Enhanced production efficiency and sustainability

Advanced Detection Capabilities

Limited detection of small or low-density contaminants, especially in complex products

Advanced pattern recognition identifies even the most challenging contaminants with up to 15% improved sensitivity

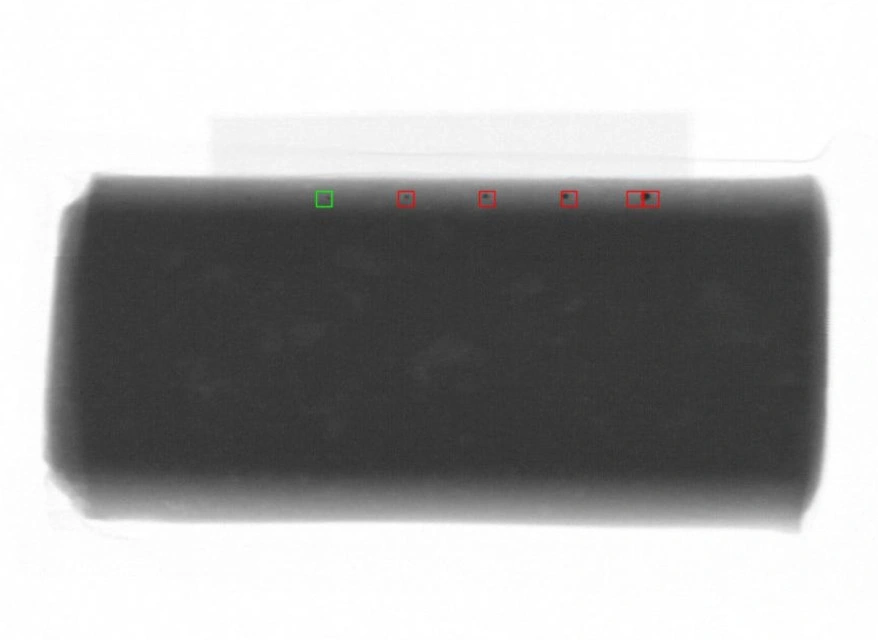

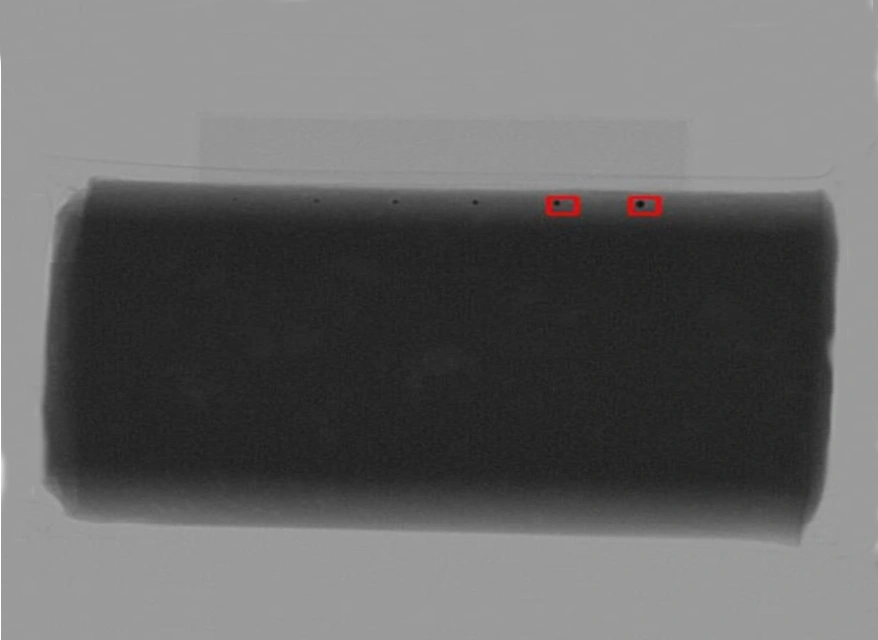

See the Difference

Use the slider to compare how MEKI AI detects small stainless steel samples in a 1.25 kg cheese block that standard inspection might miss

Quantifiable Business Impact

Understanding the financial impact of improved inspection technology is crucial for making informed business decisions. Let's examine a real-world scenario demonstrating the potential savings from implementing MEKI Assurance Intelligence.

Waste Reduction Case Study

Consider a medium-sized food production factory:

- Processing 50,000 packaged food items daily

- Product unit cost of $2.50

- Operating 365 days per year

| Standard Software | MEKI AI | Difference | |

|---|---|---|---|

| False Rejection Rate | 0.5% | 0.1% | -0.4% |

| Daily Rejected Units | 250 | 50 | -200 |

| Daily Cost of Rejects | $625 | $125 | $500 saved daily |

| Annual Savings | $182,500 |

With MEKI AI's advanced detection algorithms, this factory achieves:

- 80% reduction in false rejections

- $500 daily reduction in waste costs

- Over $180,000 annual savings in product waste alone

- Additional savings in labor and handling costs

- Improved sustainability through reduced food waste

These figures represent typical results, though actual savings may vary based on production volume, product cost, and current rejection rates.

Streamlined Compliance

Food safety isn't just about detection—it's about documentation and compliance.

Perform Critical Control Point (CCP) validation tests directly within the system, eliminating manual documentation and potential human error

Seamless integration between MEKI AI and Data Manager creates comprehensive inspection reports for audits and quality assurance

Your Path to Enhanced Inspection

Assessment

Our experts evaluate your current system and production requirements

Upgrade

Swift installation with minimal production disruption

Configuration

Product recipe creation and parameter adjustment for optimal performance

Training

Comprehensive training for your team to maximize system benefits

Ready to Transform Your Food Inspection?

MEKI Assurance Intelligence represents the future of food safety technology—combining artificial intelligence with proven inspection expertise to deliver superior protection and operational efficiency.

Contact Mekitec for a Consultation

Key Features

Enhanced Detection Capability

Up to 15% improvement in identifying low-density foreign objects

Reduced False Rejections

Decrease unnecessary product waste by up to 20% without compromising safety

Digital Validation

Paperless CCP validation tests performed directly within the inspection system

Automated Reporting

Seamless integration with MEKI Data Manager for effortless compliance documentation