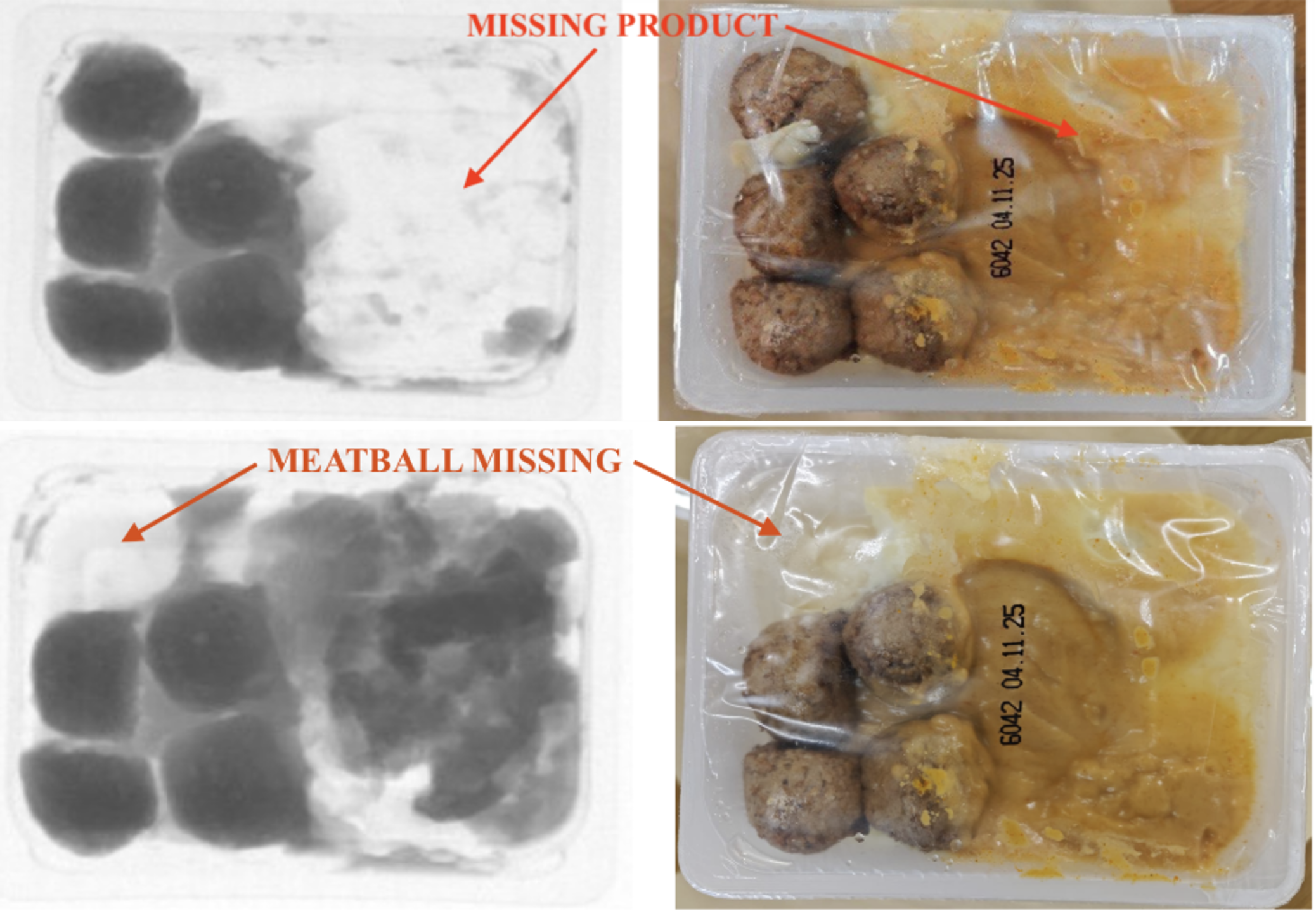

Missing Product Detection in Food Packaging

Ensure every package contains the perfect amount of product your customers expect

Perfect Fill Levels, Every Package

In today's competitive food market, customers expect consistency in every purchase. Whether it's a ready-to-eat meal, packaged snacks, or portioned products, the right amount of product in each package is crucial for customer satisfaction and brand reputation. Under-filled packages disappoint customers, while over-filled packages increase costs and waste.

Missing Product Detection technology transforms your quality control process by automatically identifying packages with incorrect fill levels, ensuring every customer receives exactly what they paid for while optimizing your production costs.

The Cost of Inconsistent Fill Levels

Incorrect fill levels create multiple problems across your operation:

- Customer complaints about under-filled packages damage brand reputation

- Negative online reviews amplify dissatisfaction and hurt sales

- Over-filled packages increase material costs and reduce profits

- Regulatory compliance issues with portion control requirements

- Manual inspection inefficiency leads to inconsistent quality

- Product waste from incorrectly filled packages

Human inspectors cannot consistently detect subtle fill level variations across all packages

Weight alone cannot distinguish between missing product and package variations

Advanced density analysis accurately identifies under-filled and over-filled packages

How It Works: Intelligent Fill Level Analysis

Our Missing Product Detection system uses sophisticated analysis to evaluate package contents and ensure proper fill levels.

Comprehensive Density Evaluation

The system automatically:

- Analyzes overall product density from X-ray images to detect fill level variations

- Evaluates distribution patterns to identify missing or excess product areas

- Compares against calibrated standards to determine acceptable fill ranges

- Provides instant feedback for immediate quality decisions

Advanced Grid-Based Assessment

Sophisticated evaluation capabilities:

- Divides packages into analysis zones for comprehensive coverage

- Calculates density percentages for each area of the package

- Identifies problem areas where product may be missing or excessive

- Maintains consistent standards across all package sizes and types

Real-World Applications

Ensure proper portions of proteins, vegetables, and sides in packaged meals

Verify consistent fill levels in bags and containers of chips, nuts, and snacks

Detect missing components in frozen dinners and multi-ingredient products

Ensure proper quantities of fillings, toppings, and ingredients in packaged baked goods

Quality Benefits You Can Measure

Before Missing Product Detection

- 3-7% variation in fill levels leading to customer dissatisfaction

- Manual spot checks catching only obvious fill problems

- Customer complaints about under-filled packages

- Over-filling costs adding 2-5% to material expenses

After Implementation

- Consistent fill levels within 1% variation across all packages

- Eliminated customer complaints related to package contents

- Optimized material usage reducing over-fill waste by up to 15%

- Enhanced brand reputation through reliable product consistency

Advanced Detection Capabilities

Missing Product Detection technology delivers:

- High-precision analysis detecting even subtle fill level variations

- Real-time assessment enabling immediate production adjustments

- Comprehensive coverage ensuring every area of each package is evaluated

- Consistent performance maintained through automatic calibration

- Flexible thresholds customizable for different product types

Integration Benefits

Missing Product Detection works seamlessly with existing MEKI systems:

Combine fill level detection with foreign object detection and other quality functions

Full traceability of fill level verification for quality documentation and trend analysis

Protecting Your Brand and Profitability

Consider the impact of consistent fill levels:

- Customer satisfaction: Ensure every package meets expectations for content and value

- Brand protection: Maintain reputation through consistent product quality

- Cost optimization: Eliminate over-filling while preventing under-filling complaints

- Regulatory compliance: Meet portion control and labeling accuracy requirements

- Operational efficiency: Reduce waste and optimize material usage

Investment That Delivers Results

For a production line processing 50,000 packages daily:

- Reduced customer complaints: 95% reduction in fill-level related issues

- Material cost savings: $2,000-8,000 monthly reduction in over-fill waste

- Quality consistency: 99%+ accuracy in fill level verification

- Brand protection: Enhanced customer trust and loyalty

Ready to Perfect Your Fill Levels?

Transform your quality control with Missing Product Detection technology that guarantees every package contains the right amount of product, protecting your brand while optimizing costs.

Contact Mekitec for a Consultation

Disclaimer: All information is provided for information purposes only and shall not be considered as assured characteristics. The information and technical data presented in this document are subject to change. Customers should obtain and verify the latest relevant information before placing orders.

Copyright 2026 Mekitec Ltd. All rights reserved

Key Features

Precise Filling Verification

Detect under-filled and over-filled packages with exceptional accuracy

Density Analysis Technology

Advanced evaluation of product density to identify missing or excess content

Grid-Based Assessment

Comprehensive analysis divides packages into zones for thorough evaluation

Quality Consistency

Maintain brand trust by ensuring consistent product quantities in every package