Seal Inspection

Protect your products and brand reputation with reliable seal integrity verification

Protecting Products Through Perfect Seals

A compromised package seal is more than just a quality issue—it's a potential disaster waiting to happen. Faulty seals lead to product spoilage, contamination, customer complaints, expensive recalls, and irreparable brand damage. In today's competitive market, ensuring every package leaves your facility with perfect seal integrity is essential for success.

Seal Inspection technology provides comprehensive protection by automatically detecting seal problems before they become costly failures, safeguarding both your products and your reputation.

The Hidden Costs of Seal Failures

Package seal failures create cascading problems throughout your supply chain:

- Product spoilage during transportation and storage

- Contamination risks that compromise food safety

- Customer complaints about damaged or leaked products

- Retail rejections of compromised packages

- Brand damage from poor quality perception

- Regulatory compliance issues and potential recalls

Human inspectors miss subtle seal defects and can't check every package consistently

Traditional methods only catch obvious failures, missing critical early-stage problems

Automated detection identifies both obvious and subtle seal integrity issues with every package

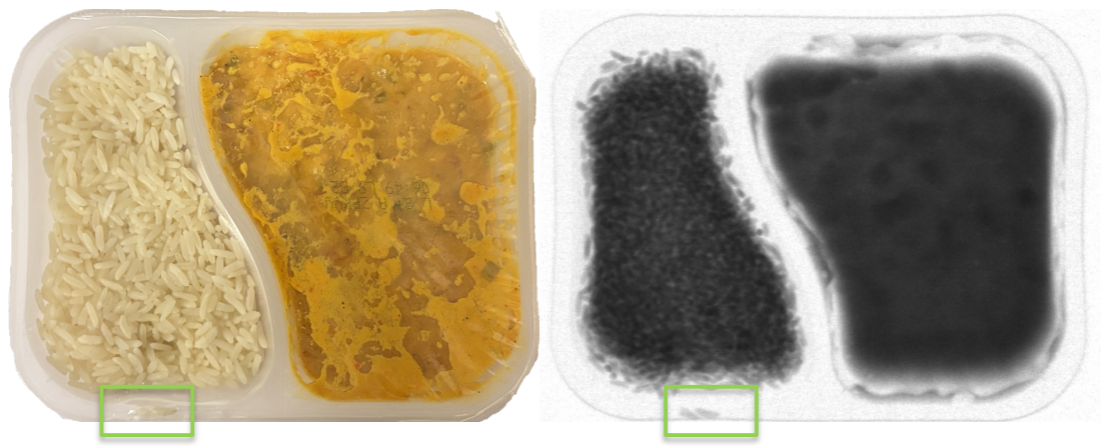

How It Works: Comprehensive Seal Protection

Our Seal Inspection system provides thorough analysis of every package seal to ensure complete integrity.

Intelligent Package Analysis

The system automatically:

- Recognizes package boundaries regardless of shape or material

- Identifies seal areas where integrity is critical

- Detects product intrusion into seal zones that could cause failure

- Adapts to different packaging types and sealing methods

Complete Seal Verification

Advanced inspection capabilities:

- Scans entire seal perimeter for any signs of compromise

- Identifies trapped product material that indicates poor sealing

- Detects incomplete seals before they cause leakage

- Works with any packaging from flexible pouches to rigid containers

Real-World Applications

Prevent spoilage in sealed food products by ensuring airtight package integrity

Detect seal defects in bottles, cans, and pouches before carbonation loss or contamination

Ensure sterile packaging integrity for pharmaceutical and medical device packaging

Protect product quality in sealed containers for household and personal care items

Universal Packaging Compatibility

Seal Inspection works effectively with:

Pouches, bags, and flexible films with heat seals, crimp seals, or adhesive closures

Bottles, jars, cans, and boxes with various lid and closure types

Irregular shapes, curved surfaces, and multi-component packaging systems

Quality Benefits You Can Measure

Before Seal Inspection

- High spoilage costs from compromised products

- Customer complaints about leaked or damaged items

- Manual inspection catching only obvious defects

After Implementation

- Eliminated spoilage costs from undetected seal problems

- Improved customer satisfaction with consistently intact products

- Complete automated verification of every package

Integration Benefits

Seal Inspection works seamlessly with existing MEKI systems:

Combine seal inspection with foreign object detection and other quality functions

Full traceability of seal verification results for quality assurance and compliance

Protecting Your Investment

Consider the value of preventing seal failures:

- Spoilage prevention: Eliminate losses from products that deteriorate due to seal failure

- Brand protection: Maintain customer trust with consistently high-quality packaging

- Recall prevention: Avoid costly recalls by catching problems before products ship

- Customer satisfaction: Ensure products reach consumers in perfect condition

- Regulatory compliance: Meet packaging integrity requirements across all markets

Ready to Ensure Perfect Seals?

Transform your packaging quality control with Seal Inspection technology that guarantees every product leaves your facility with perfect seal integrity, protecting both your customers and your brand.

Contact Mekitec for a Consultation

Disclaimer: All information is provided for information purposes only and shall not be considered as assured characteristics. The information and technical data presented in this document are subject to change. Customers should obtain and verify the latest relevant information before placing orders.

Copyright 2026 Mekitec Ltd. All rights reserved

Key Features

Comprehensive Seal Detection

Identify broken, open, or compromised seals across all packaging types

Product Contamination Prevention

Detect when product material is trapped in seal areas, preventing leakage

Universal Packaging Support

Works with any package shape, size, or sealing method

Brand Protection

Prevent spoiled products from reaching consumers and damaging reputation