Foreign Object Detection in Food Production: Ensuring Safety with X-Ray Technology

Understanding Foreign Object Detection in Food Manufacturing

Food safety remains a top priority for manufacturers worldwide. With various inspection technologies available, choosing the right system for detecting foreign objects has become essential for protecting consumers and maintaining brand reputation.

The Nature of Food Safety Hazards

The FDA's HACCP Principles define a hazard as "a biological, chemical, or physical agent that is reasonably likely to cause illness or injury in the absence of its control." Among these, physical contaminants pose unique challenges that X-ray inspection systems are particularly well-suited to address.

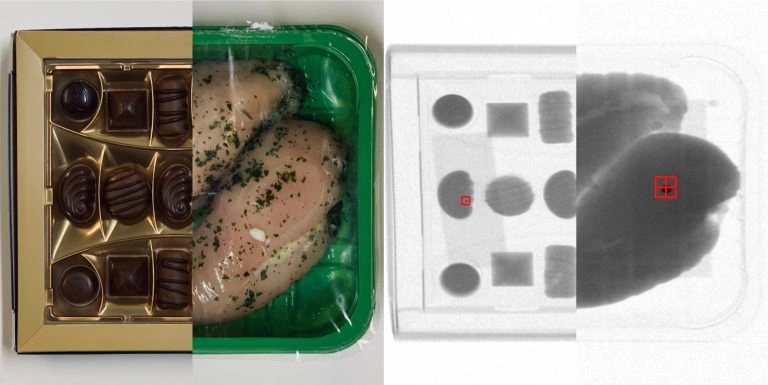

X-ray technology has emerged as a leading solution because it can detect contaminants through any packaging material, regardless of product moisture or salt content. This versatility makes it invaluable for modern food production lines.

Types of Foreign Objects and Their Risks

Not all foreign objects pose the same level of risk to consumers. Understanding these differences helps prioritize inspection efforts.

Low-Risk Contaminants

While unpleasant, materials like hair or paper fragments rarely cause physical injury. However, their presence can still damage consumer confidence and brand reputation.

High-Risk Materials

More dangerous contaminants include:

- Metal fragments from equipment wear

- Glass pieces from broken containers

- Stones from raw materials

- Dense plastics or rubber

These materials can cause serious injury and must be reliably detected and removed from the production stream.

Building an Effective Detection Strategy

Prevention First

The best approach combines prevention with detection. Simple measures like requiring hairnets, limiting glass near production areas, and maintaining equipment properly can significantly reduce contamination risks.

Establishing Critical Control Points

Successfully implementing foreign object detection requires careful planning:

- Risk Assessment: Evaluate your entire production process to identify where contaminants might enter. Consider raw materials, equipment condition, and environmental factors.

- Technology Selection: Conduct application tests with actual products to determine which inspection technology performs best for your specific needs.

- Strategic Placement: Position inspection systems at critical points where they'll catch contamination before products reach consumers.

Making X-Ray Inspection Work for You

Installation and Validation

When implementing X-ray inspection:

- Test all product variations to ensure consistent detection

- Train operators thoroughly on system capabilities and limitations

- Establish clear procedures for handling rejected products

Ongoing Monitoring

Success depends on continuous vigilance:

- Regular performance checks ensure systems maintain sensitivity

- Detailed records demonstrate due diligence to auditors

- Trend analysis helps identify recurring issues

When Contamination Occurs

Despite best efforts, contamination incidents may still happen. Having clear corrective action procedures helps:

- Quickly identify and address root causes

- Prevent similar incidents in the future

- Demonstrate commitment to continuous improvement

Beyond Foreign Object Detection

Modern X-ray systems offer additional quality control benefits that enhance overall product integrity:

- Verify fill levels and product completeness

- Check seal integrity

- Count components in multi-pack products

- Generate valuable production data for quality improvement

These capabilities transform X-ray inspection from a simple safety measure into a comprehensive quality assurance tool that protects both consumers and your brand reputation.