Food X-ray Inspection Safety: Protecting Quality and Health in Food Production

When it comes to food safety and quality control, X-ray inspection has become an indispensable technology in modern food production. Yet, concerns about radiation exposure often arise among operators and facility managers. Let's explore the science behind X-ray inspection safety and understand why these systems are both effective and safe for everyday use in food production environments.

Understanding Radiation: Breaking Down the Basics

Before diving into the specifics of food X-ray inspection, it's essential to understand what radiation actually is and how different types affect us. This knowledge forms the foundation for appreciating why X-ray inspection systems are designed with multiple safety layers.

Non-Ionizing vs. Ionizing Radiation

Radiation exists all around us, but not all radiation is created equal. Non-ionizing radiation, which includes everyday sources like visible light, UVA rays from the sun, and microwaves from our phones, lacks the energy to alter chemical bonds in materials. It's the type of radiation we encounter constantly without concern.

Ionizing radiation, on the other hand, carries enough energy to potentially break molecular bonds. This category includes cosmic radiation from space, naturally occurring radon from the ground, and the controlled radiation used in medical and industrial X-ray devices. While ionizing radiation requires careful management, modern X-ray inspection systems are engineered to minimize exposure to levels far below natural background radiation.

Measuring Radiation: Understanding the Numbers

When evaluating radiation safety, understanding measurement units helps put exposure levels into perspective. The industry uses several units to measure radiation's biological effects:

The sievert (Sv) serves as the primary unit, with common conversions including:

- 1 Sv equals 100 rem

- 1 rem equals 10 millisieverts (mSv)

- 1 mSv equals 100 millirem (mrem)

- 1 mrem equals 10 microsieverts (μSv)

These measurements help us compare X-ray inspection exposure to everyday radiation sources we encounter naturally.

Real-World Radiation Levels in Food X-ray Inspection

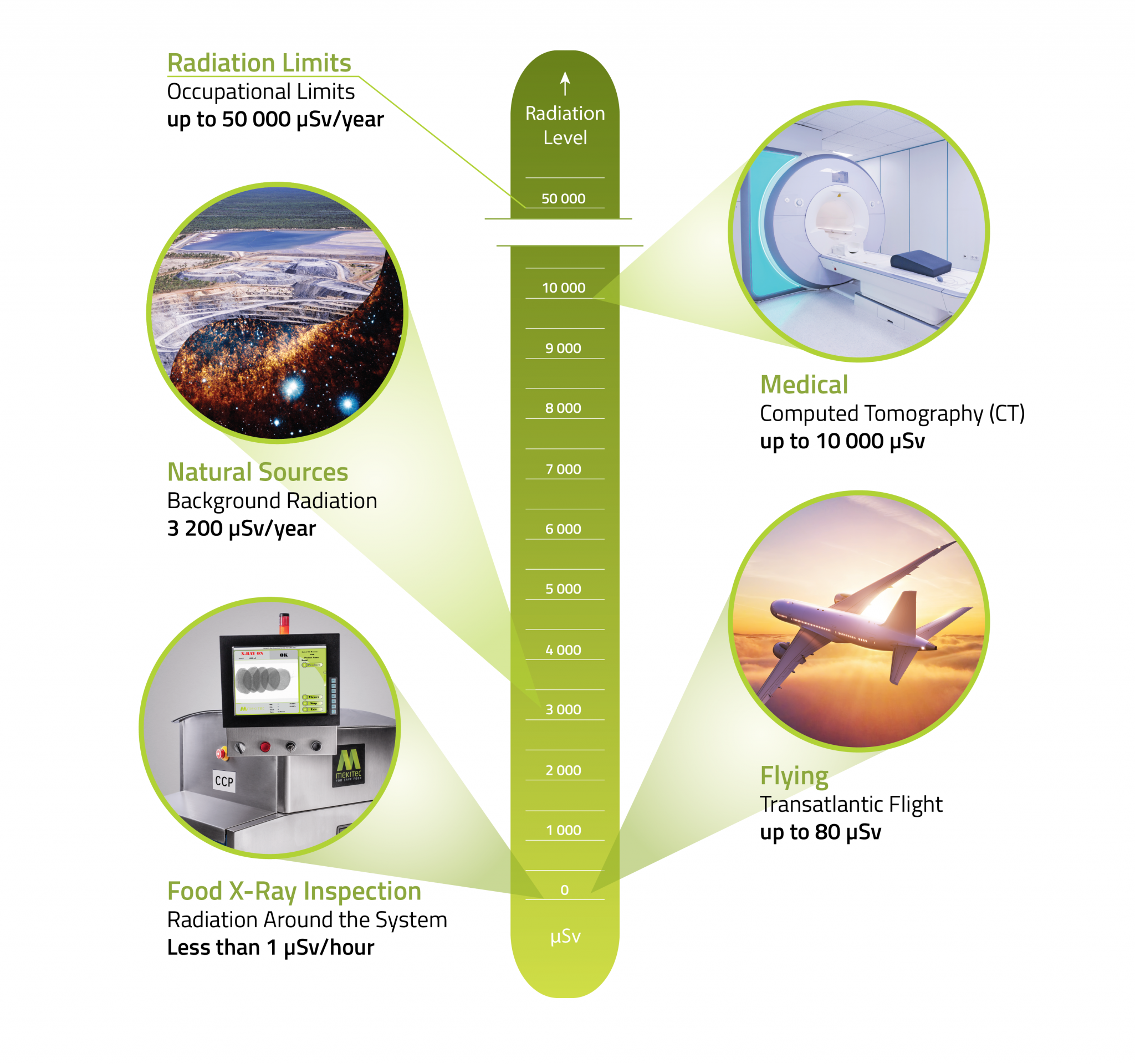

Here's where the safety of X-ray inspection becomes clear. Modern food X-ray inspection systems emit remarkably low levels of radiation—approximately 0.1 μSv per hour in typical production environments. To put this in perspective, the natural background radiation we're exposed to daily averages around 0.4 μSv per hour, meaning the X-ray system adds only a fraction to what we naturally encounter.

International safety regulations mandate that X-ray inspection systems maintain radiation levels below 1 μSv per hour at operator positions—a standard that modern systems easily exceed with their advanced shielding technology.

What This Means for Operators

Even in scenarios of continuous exposure, operator safety remains well-protected. An operator working a full 8-hour shift near an X-ray inspection system would accumulate approximately 1,200 μSv of exposure. This amount falls far below annual occupational limits, which range from 20,000 to 50,000 μSv depending on regional regulations.

To provide another comparison, this yearly exposure equals roughly the radiation received during eight round-trip flights—a level many business travelers routinely experience without concern.

Advanced Safety Features in Modern X-ray Systems

Today's X-ray inspection systems incorporate multiple safety features that work together to minimize radiation exposure. Stainless-steel cabinets provide robust containment, while specialized shielding materials block X-rays from escaping the inspection chamber.

High automation levels further enhance safety by reducing the need for operators to interact directly with the system during operation. These design elements create a working environment where radiation exposure remains minimal, allowing staff to focus on quality control without safety concerns.

Food Product Safety: Addressing Common Concerns

A frequent question involves whether X-ray inspection affects the food products themselves. The answer is reassuringly straightforward: X-ray inspection is completely safe for all food types, from fresh produce and organic items to processed foods and high-value nutraceuticals.

Products pass through the X-ray beam for mere seconds, receiving minimal energy that dissipates immediately. Unlike radioactive contamination, X-rays don't make food radioactive or alter its nutritional properties. The World Health Organization and food safety authorities worldwide have validated X-ray inspection as a safe, non-invasive method for ensuring food quality.

Best Practices for Maximizing X-ray Inspection Safety

While modern X-ray systems are inherently safe, following best practices ensures optimal safety and compliance:

Start by understanding and complying with local radiation safety regulations, which vary by region but all prioritize operator protection. Always follow the manufacturer's usage instructions and maintenance schedules, as proper system care maintains safety features at peak effectiveness.

Regular maintenance checks ensure shielding integrity and proper system function. Many facilities also benefit from designating a Radiation Safety Officer (RSO) who oversees safety protocols and maintains compliance documentation.

Training staff on proper operating procedures and safety awareness creates a culture of safety that extends beyond just radiation concerns to overall workplace well-being.

Moving Forward with Confidence

X-ray inspection technology represents a crucial advancement in food safety and quality control. By understanding the science behind radiation safety and recognizing the extensive protections built into modern systems, food producers can implement these technologies with confidence.

The combination of minimal radiation exposure, comprehensive safety features, and proven effectiveness makes X-ray inspection an ideal solution for facilities prioritizing both product quality and workplace safety. As the food industry continues evolving toward higher safety standards, X-ray inspection stands as a testament to how advanced technology can enhance operations while maintaining the highest safety standards.