Advancements in Food Inspection: From Metal Detection to Mekitec X-Ray with Data Manager

In the ever-evolving landscape of the bakery industry, ensuring the safety and quality of baked goods is paramount. From the earliest days of metal detectors to the cutting-edge advancements of MEKI X-Ray systems with Data Manager, inspection technology has played a vital role in safeguarding consumers and maintaining the integrity of bakery products.

The journey of food inspection technology began in the 1960s with the introduction of metal detectors. In the 1990s, the food inspection witnessed a significant leap forward with the adoption of X-ray technology in to the food production. Fast forward In 2023, the bakery industry embraces X-ray inspection, digitalization, and advanced data management, revolutionizing bakery production with a comprehensive and efficient approach.

1960: Metal Detection

Metal detectors revolutionized food production in the 1960s by enabling the detection of metallic contaminants. This technology played a vital role in ensuring food safety by identifying any foreign metallic substances in the production line.

1990: X-ray Technology

In the 1990s, X-ray technology emerged as a critical control point in food production. It surpassed the capabilities of metal detectors by detecting not only metallic contaminants but also non-metallic hazards like stones, glass, ceramic, and bone fragments. X-ray systems also offered the ability to inspect filling, detect missing items, and analyze products with metallic closing clips or aluminum packaging.

2023: Mekitec X-Ray with Data Manager

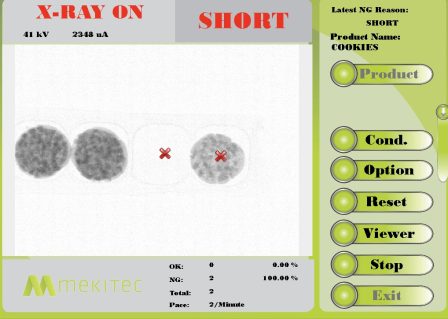

In 2023, Mekitec introduced the X-Ray with Data Manager, a cutting-edge solution that digitalizes data collection and audits for X-ray systems. This innovation streamlines critical control point audits, enhances traceability of production data, centralizes quality and production data gathering, provides real-time monitoring of key performance indicators, and enables comprehensive analysis and optimization of production processes.

From metal detection to the Mekitec X-Ray with Data Manager, the food industry has experienced remarkable advancements in inspection technology. These innovations have greatly improved food safety, quality, and overall production efficiency. As technology continues to evolve, we can anticipate even more exciting developments that will further enhance food inspection processes and ensure the continuous improvement of our food supply chain.

Protect Your Customers and Brand

Physical contamination in baked products can put your customers at risk and lead to product recalls. By choosing Mekitec X-ray solutions as your bakery production line’s Critical Control Point (CCP), you can reduce the risks and increase the quality of your production.

At Mekitec we know, that the greatest value is achieved by inspecting primary packed products at the end of the packaging line.

This not only ensures the highest level of inspection accuracy in foreign object detection, but also enables the use of other value-adding inspection functions like AI-based quality inspections.

Moreover, inspecting products at this stage reduces food waste and eliminates the risk of further contamination since the product is packed, increasing food safety. It also provides a wealth of production line data that can be analyzed to optimize quality, productivity, and other Bakery key performance indicators.

Optimize Your Bakery Production With Mekitec Data Manager

Are you looking for a solution to optimize your bakery production and improve product quality? Mekitec Data Manager can help. Our software, integrated with our X-ray systems, allows you to easily track, analyse, gather and manage data from multiple production lines and locations.

With Data Manager, you can generate customizable reports on production data, such as foreign object detections, product rejection rates and the performance of the production. This data can be used to make informed decisions about your production processes, streamline operations and improve product quality.

The digitalization of the Critical Control Point (CCP) audit process is a key feature of Data Manager, easing the workload for quality and production managers. Our software automates data collection and analysis, allowing for quicker identification of potential issues and streamlining the auditing process.

In the bakery industry, where production often runs 24/7, remote monitoring is crucial. Data Manager provides real-time data on production line performance, allowing managers to stay connected and make informed decisions from anywhere.

Optimize your bakery production with Mekitec Data Manager. Contact us today to learn more about how our software can help improve your bakery operations