More Reliable

and Cost-Effective

Packaging

Inspection

Packaging Inspection

Foreign object in food poses a huge safety risk if they end up in the hands of consumers. It is demanded that food producers establish Critical Control Points (CCPs), where they check the safety of their products before shipping them out to customers and ultimately to consumers.

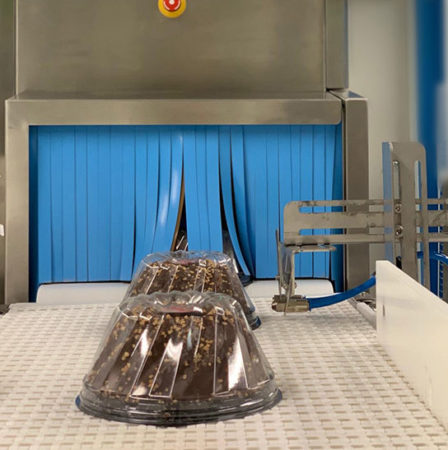

It is important that the inspection happens after the food product is packaged and sealed and there is no possibility for any further contamination. This can be executed by choosing primary packaging inspection over secondary, and the most efficient way to inspect packaged products is to use an X-ray system.

THE ADVANTAGES OF PRIMARY PACKAGING INSPECTION

Oftentimes food manufacturers think that installing an X-ray system can be costly or complex, and they might be tempted to install only a few systems as close to the end of the packaging process to inspect the secondary packaging. However, there are multiple reasons why installing an X-ray system to do the primary packaging inspection is much more convenient and efficient.

The X-ray system is able to detect various physical contaminants from the product, as well as perform other quality inspections simultaneously. When the system is placed in the primary packaging area, the food producer can benefit from all the valuable functions that the Mekitec X-ray inspection system has to offer, such as content inspection (e.g. fill level monitoring, shape and form inspection) and more accurate detection rate.

Placing an X-ray system in the secondary packaging area, meaning the inspection of entire cases or cartons, might seem initially attractive, but the reduced detection accuracy and higher maintenance costs outweigh the other cost-related advantages. When the X-ray system is placed in the secondary packaging inspection area, the other valuable quality inspection features of the system cannot be used as efficiently as in the primary packaging inspection.

MORE RELIABLE AND COST-EFFECTIVE PACKAGING INSPECTION

Primary packaging inspection is proven to be a more reliable and cost-effective strategy for food producers to guarantee their product safety and quality. Secondary packaging inspection often provides less value to the food producers, since they cannot benefit from the additional functions that Mekitec X-ray systems offer.

When inspecting single packages, the X-ray system also allows to track the products going through the system, trace the possible contaminations, calculate the pack rate, and time stamp rejections.

If contamination is detected, the system will only reject the single package and not the whole carton, thus creating less waste.

The primary inspection systems are usually much smaller in size and require lower X-ray power. Mekitec X-ray inspection system uses a low-energy X-ray generator, and that’s why it is most suitable for single package inspection. This also enables us to reach the highest level of foreign object detection.

Learn Why Food Producers Should Inspect Primary Packagingwhite paper

More information about Primary Packaging Inspection

Fill in the form to download our white paper about primary packaging inspection and learn how inspecting single packaged products can tremendously improve the foreign object detection rate, reduce waste, and more.