Primary packaging inspection

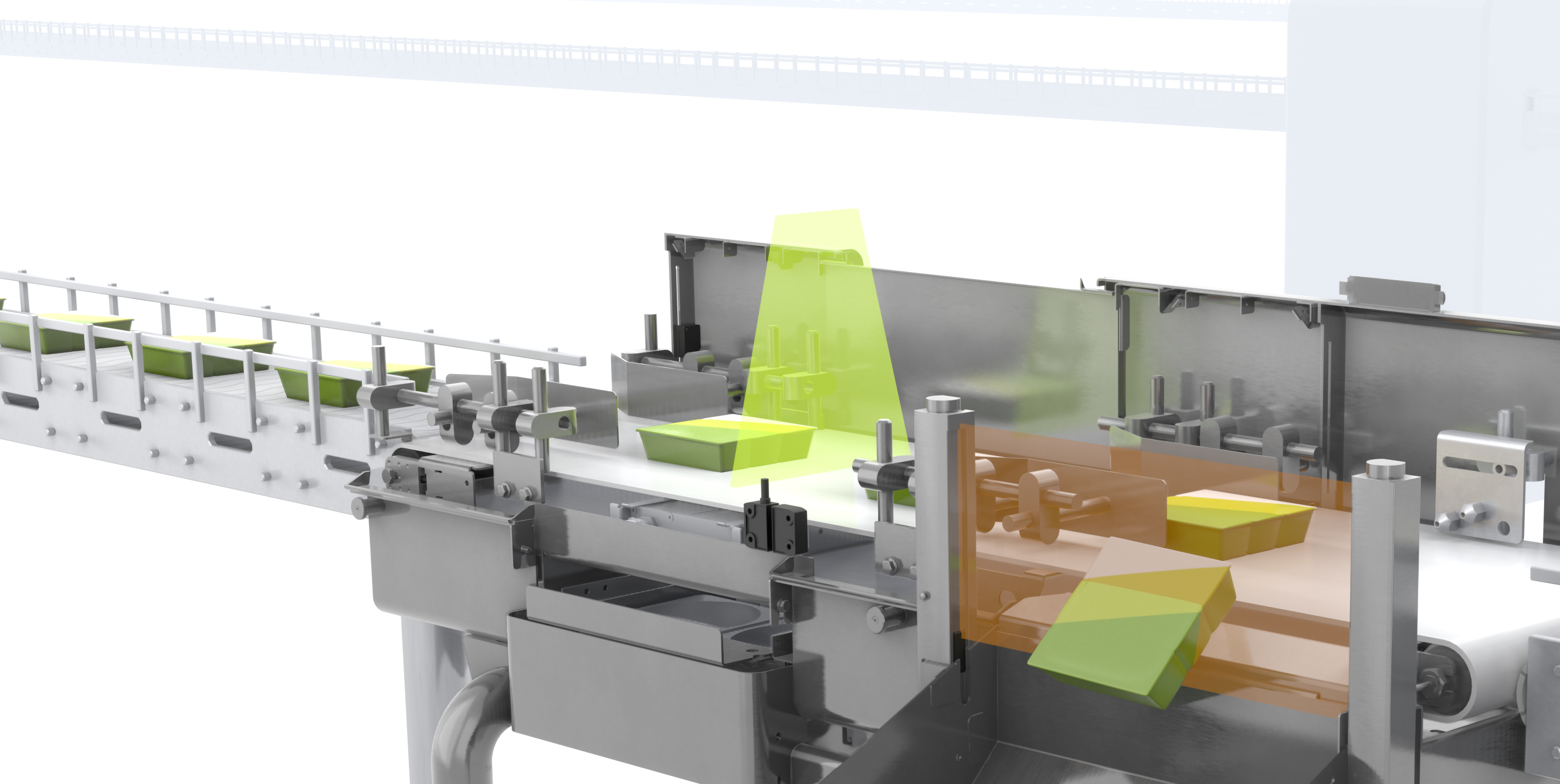

with Mekitec X-ray imaging systems

Primary packaging inspection in the global food industry

What is primary packaging inspection? There are three main stages in food production where the producers can implement product inspection and a critical control point: bulk production, primary packaging, and secondary packaging. After the raw material is processed, food products continue their way to packaging. Once the food products are packaged and sealed, they can no longer be contaminated without breaking the packaging material. This makes the packaged products ideal for food safety control and quality inspection.

In primary packaging, food manufacturers will benefit from the most accurate detection rates of foreign contaminants compared to secondary packaging inspection. This is because the systems are looking at individual food packages with fewer variations between the inspected products and the inspection can be finetuned to be much more precise than with secondary packaging inspection systems.

Read the in-depth comparison between these three inspection options from our blog: Bulk, primary, or secondary packaging inspection? or sign up for the “Multiply food safety with primary packaging X-ray inspection” webinar recording to find out more.

There are multiple reasons why installing a primary packaging inspection system to inspect individual, consumer-packaged products, is a much more beneficial and efficient choice. Keep reading to learn how inspecting single packaged products can tremendously improve the foreign object detection rate, reduce waste, and more.

Why should food producers use primary packaging X-ray inspection in their production?

In the primary packaging stage, food producers have yet another crucial decision to make: which inspection technology to choose? All the options such as X-ray systems, metal detectors, and vision systems have their own advantages as well as some limitations regarding the product safety inspection. Read more about these three inspection options and their pros and cons from our blog.

When comparing the three different inspection solutions (X-ray, metal detection, and vision), it quickly becomes obvious that X-ray technology provides the best and most of the benefits to food producers. With X-ray inspection systems food producers can, for example, detect unwanted quality defects such as broken or missing products to ensure that they deliver only top-quality products to their customers and consumers. All of this while simultaneously having the foreign object detection for metallic and non-metallic contaminants alike.

When choosing primary packaging X-ray inspection, food producers get the latest and greatest inspection solution with the most accurate detection rates and pack-for-pack traceability, just to mention a few advantages.

What are the benefits of primary packaging X-ray inspection?

At Mekitec we will meet all of your requirements, whether you’re seeking for increased inspection accuracy, increased product safety and quality, or functions for quality control and traceability. Additionally, our primary packaging X-ray inspection can help you reach the benefits listed below.

Primary packaging X-ray inspection helps food producers to:

-

- Maximize product safety and overall quality

- Secure that no further contamination can happen without breaking the package

- Improve inspection accuracy and performance to detect smaller contaminants

- Decrease the amount of false rejections

- Save production space and money with the smallest system size

- Accurately apply all the available quality control functions to detect misshaped, broken, or missing parts of the products

- Build a sustainable production by reducing waste

- Improve the production efficiency by giving real-time feedback from any process changes or development actions

- Trace contaminations, calculate pack rate and time-stamp rejections and implement the latest traceability functionalities

- Avoid any bottlenecks and maintain the highest production efficiency despite any potential system failure when implementing the inspection to individual lines

- Significantly decrease the number of consumer reclamations and build a stronger food brand

- Meet and exceed consumer and retail chain quality expectations

Read more about the benefits of primary packaging X-ray inspection in the food production environment from our blog:

7 reasons why food producers should inspect primary packagingMultiply food safety with Mekitec primary packaging X-ray systems

Many producers may find it appealing to install X-ray equipment for secondary packaging or for bulk/unpacked production inspection purposes at first. However, today the implementation of primary packaging X-ray inspection provides food producers with improved detection rates as well as full traceability and quality functions all at lower investment costs and total costs of ownership.

Mekitec has made primary package X-ray inspection accessible and available for small and large food producers alike to get the greatest inspection technology, better inspection performance, and best value for your investment, eliminating the need for compromises in food quality control!

Multiply food safety and enhance food production with these four steps:

- Pay attention to the placement of the CCP (primary packaging is recommended)

- Utilize the best technology available

- Gather and use data to optimize

- Use all the consultation help you have available

Get the Best Value from Your CCP

There are multiple reasons why installing an X-ray system to inspect the primary packaged products is much more beneficial and efficient.

Mekitec has made X-ray inspection truly accessible for small and large food producers alike, offering better inspection performance and best value for your investment – now, there is no more need for compromises in food quality control!

Download our eBook to learn how to take your CCP to the next level and achieve better detection performance in your food production.

E-book: How to get the best value from a Critical Control Point