EXPANSION TO NEW MARKETS IN COMPETITIVE READY-TO-EAT FOOD INDUSTRY

Ready-to-eat meal industry is well-known of its very competitive nature. Rapidly changing trends in the market challenge companies to respond to the fast dynamic changes in consumers’ wants and needs. Social media has also its role in leading opinions and negative information spread easier than ever before, causing unexpected damage to brand image. Positive information, on the other hand, may cause unpredictable peaks in the demand and require more attention to the production optimization and quality issues.

In general, well-established quality brands are rewarded with good revenue, but food conscious consumers are aware of inconsistency in quality, new ingredients and product offerings. The consumers’ growing willingness to switch brands more easily has arisen the food manufacturers’ need for finding new options to differentiate from competitors, maintain the customer base and preserve customer satisfaction. The tightening standards and quality requirements can create challenges when food companies are looking to expand globally. Also, the expansion to bigger markets leads to growth in production volumes and increases the risk for costly recalls. The potential financial damage can be catastrophic along with the lost brand image, if foreign objects, that can be dangerous for health, are found in the food products.

The Swedish ready-to-eat food producer is a good example of how to answer the challenges relating to differentiation and expansion. The company had positioned itself well in the market, being a producer for a private label of a large multi-national vendor. Before the co-operation could be started, quality control and safety audits were required. Success in the audits opened a large new market for the Swedish producer and solidified the contract with the vendor. One important part of the audit was the inspection of packaged products. To ensure the product quality and safety, the company started to source the best partner for quality control.

QUALITY CONTROL FOR READY-TO-EAT FOOD

Since ready-to-eat meals are made of different ingredients that are usually either fresh food, such as vegetables or berries gathered straight from the nature, and/or meat, dairy or other processed food products, the quality of the end-product is in a high role. Usually, the food transitions are crucial in this type of a production where the different ingredients are gathered from earlier stages of the production, possibly being produced and/or delivered by a third party, making it difficult to ensure the quality beforehand. As ready-to-eat products are consumed straight out of the packaging without the need for preparing or cooking, the risks relating to foreign objects represent an even greater danger for consumers. These risks are not relating only to metal objects since foreign object contamination is more often glass, stones, or plastic rather than metal. In ready-to-eat food industry, is is also important to inspect if there is broken, missing, or incomplete products in the production.

A REALIZED SOLUTION FOR SWEDISH PRODUCER: MEKITEC’S X-RAY QUALITY CONTROL TECHNOLOGY

After evaluating various inspection system vendors, the Swedish producer realized that the more sophisticated the X-ray technology, the higher the price compared to metal detectors. However, the advantages over X-ray systems compared to metal detectors as well as a recommendation from a peer led the company to look at Mekitec’s X-ray food inspection systems.

At first, the company contacted Mekitec for more information about X-ray solutions. The discussions with Mekitec’s representatives convinced the company of the X-ray vendor’s professionality and ability to meet their needs. The company was happy for the professional and friendly service they encountered during the whole process from the beginning of the first inquiry to the end of setup and training. The whole process took only one month, and after that, they successfully accomplished the audit and made the co-operation contract with the vendor possible.

High lifetime value with MEKI solutions

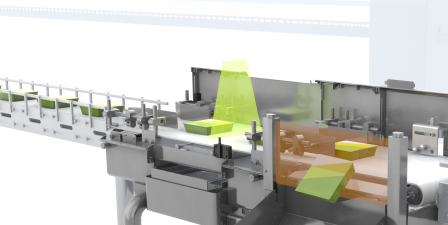

The MEKI X-ray food quality control system, that the Swedish producer and co-packer chose, is light, versatile and easy to install seamlessly in almost any production line without taking too much of space. MEKI’s unit prices are also cost-effective as they are designed especially for primary packaging lines enabling food manufacturers to increase detection accuracy and traceability while reducing the amount of production waste.

In many cases, the smallest contaminant that the MEKI X-ray can detect is even smaller than 1mm in size. The ready-to-eat-food products have heterogeneous density inside the product, due to various ingredients inside such as salads, sandwiches, wraps and other products. Even with these obstructions, the MEKI could detect 1.5mm metal as well as glass and stones from the products. The X-ray system is not only able to inspect these small foreign objects but also the overall shape and structure of the food and its package. It can detect missing dressing pouches from salads, which is an example of a very common concern in customer complaints in this industry.

The X-ray system saves the image of each product and rejects the poor-quality ones automatically. The data gathered from the system is beneficial for comparing the performance of different production lines and optimizing them. It allows full traceability to the production by tracing contaminants and defects from factory to stores as well as up-stream in the production process.

Finding a cost-effective partner for quality control, Mekitec’s MEKI X-ray quality control solutions are an advantage. Passing an important audit or gaining an access to new markets are just a few examples of how Mekitec’s comprehensive X-ray quality control systems offers a smart solution to various challenges that food producers encounters. Food quality control is not just a mandatory investment, it can also be a solution that creates real value for everyone: food manufacturers, retailers and consumers.

Read More About Road To Safe Food

Ready-to-Eat

Detect and remove these contaminants using Mekitec's food X-ray inspection systems.

Read moreRadiation Safety in Food X-Ray Inspection

Food X-ray inspection is safe for the operating staff and the inspected products. Read more on our blog about radiation safety!

Read moreForeign Object Detection in Food Production with X-Ray

What are the factors you should focus on when deciding between different inspection systems?

Read more