Detect Safety Hazards

from Cheese Products

with X-ray Inspection

How to Ensure the Safety of Your Cheese Products?

Cheese producers should make sure their products are on par with retailer and consumer standards and expectations, but most importantly that the products are safe to consume.

It doesn’t matter if your cheese products are in blocks, sliced or shredded form, it is important to ensure they are free from any physical contaminants, such as metals, glass or other high-density objects.

In this blog, we go through some common problems that cheese producers may encounter when selecting the most suitable inspection method for their operations and also offer a solution to this problem!

The Problem

Cheeses, like many other dairy-based products, have conductive properties, such as high moisture and salt levels, in them which can narrow down the suitable inspection methods.

Sometimes, cheese producers can even find it challenging to perform the final product inspection with metal detectors due to these conductive properties that can disturb the metal detector’s magnetic field, causing the system to alert for metal contamination when in reality there isn’t one. This can lead to unwanted false rejects that add the amount of waste in the production environment.

Read more about X-ray technology versus metal detection here:

X-Ray vs. Metal DetectorThe Solution

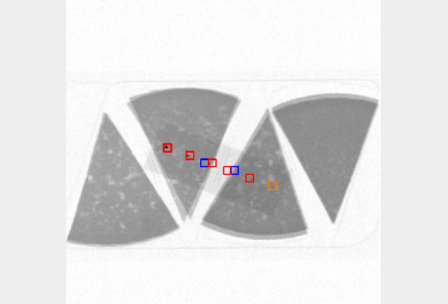

To encounter the aforementioned issue, cheese producers have turned to food X-ray inspection that enables more accurate inspection, regardless of the conductive properties that the cheese products have.

Since the technology is based on density differentials within the product and the properties of the foreign matter, X-ray systems are able to detect various quality defects and foreign contaminants – be it metal, stone, glass or any high-density object that could be hazardous if consumed.

As established in our eBook “How to Get the Best Value from a CCP in Food Production”, the product should be inspected in the primary packaging phase, where the cheese products are already sealed in single packages, allowing no further contaminations during the production process, but not yet placed in a larger box or carton. This placement enables the most accurate inspection and higher detection rates for any possible quality defects and contaminants when choosing an X-ray inspection system as your Critical Control Point.

our e-book

Level Up Your Food Production!

After reading our eBook How to Get the Best Value from a Critical Control Point in Food Production you will know how to successfully implement an inspection system into your food production to ensure only the safest and highest of quality products are delivered to your customers.

The eBook explains what is expected from a CCP now and in the future, and why you too should inspect primary packaged products.

Fill in the form and you will receive the eBook to your inbox for free!