What is

Foreign Object

Detection

in the Food Industry?

Foreign Object Detection in Food Production with X-Ray

Nowadays food producers have many options when it comes to the detection of foreign objects from food production lines. What are the factors you should focus on when deciding between different inspection systems?

First off, let’s determine what is a food safety hazard. According to the Food and Drug Administration’s (FDA) “HACCP Principles and Application Guidelines” a hazard (meaning a risk to safe food) is “a biological, chemical, or physical agent that is reasonably likely to cause illness or injury in the absence of its control.” X-ray inspection systems are used in order to detect and eliminate foreign objects in food products.

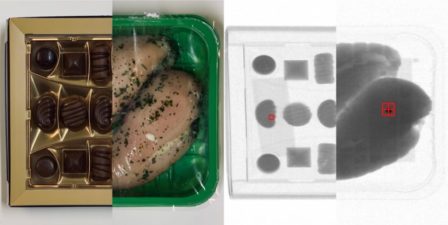

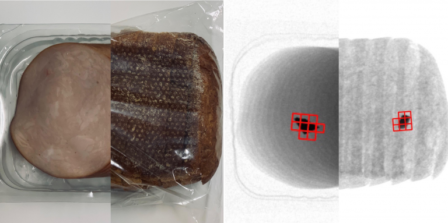

The foreign objects in food products can be various materials, such as stainless steel, glass, or stones. With X-ray, these contaminants are detected regardless of the packaging material, and the product’s high moisture or salt content won’t affect detection rates.

How to detect hazardous foreign objects in food production?

Physical agents (a.k.a. foreign objects or bodies) are any undesirable, solid objects in food. They can be divided into hazardous or non-hazardous contaminants.

For example, non-hazardous contaminants such as hairs or paper (although unpleasant) will not endanger or injure the consumer if found in the food product.

In order to control foreign objects such as these, effective processes should be put in place to avoid the initial contamination. These processes can mean the use of appropriate protective clothing and hairnets etc., as well as limiting the use of materials that could contaminate the naked product.

Contaminants such as metals, glass, and stones are classified as hazardous foreign objects. Detecting hazardous foreign objects in food products requires a Critical Control Point (CCP) that inspects each food product and automatically rejects contaminated ones from the production line.

How to Prevent and Eliminate Foreign Objects in Food Production?

A proper HACCP plan should be introduced in order to prevent foreign objects from ending up in the finished food product. A good plan will also help food producers manage the quality of raw material vendors and remove foreign objects effectively from the production.

There are requirements in the HACCP framework, that obligate food producers to set up control points with critical limits to ensure that the product safety is at an acceptable level.

Typically, food producers use metal and/or X-ray inspection for foreign object detection in food production as their Critical Control Points. Both technologies are commonly used, but there are reasons why X-ray inspection is becoming a more popular inspection method.

Read more about the Advantages of Food X-ray InspectionIMPLEMENTING FOREIGN OBJECT DETECTION IN FOOD PRODUCTION

There can be massive consequences if contaminated food products end up in the hands of consumers. That’s why foreign object detection is the key to protect your customers and your brand.

There are multiple reasons why contaminated products are bad for the business, such as costly product recalls, loss of brand loyalty, and most importantly the injury it could cause to consumers.

To fully prevent physical contaminations, it is important to know where your foreign objects are coming from. The goal is to find the possible hazards as early as possible in your production process. This is one reason why inspecting large cases just before the shipment is not a very effective practice compared to a single packaging inspection.

3 key points you should know about the implementation of foreign object detection

- Identify Potential (Hazardous) Foreign Objects in Food

Identifying the possible dangerous foreign objects that may present a food safety hazard if not removed before they reach the consumers, is the first step in the HACCP Plan. This should be done also for the raw materials used, and their respective vendors.

- Establish Critical Control Points and Critical Limits

There is not one fixed global standard to base the critical limits on, but instead, food producers should conduct proper application tests with the quality control system vendor to determine the performance level on their products, as well as the best placement for the CCP system. There are some guidelines for the critical limits, e.g. many retail chains have their own expectations on the performance for CCPs, and the FDA has set certain limits for contaminants that may present a choking hazard for a newborn baby.

- Implement Inspection System to Detect Foreign Objects in Food

A well-executed implementation process together with the necessary application/product tests, deciding on the critical control point performance limits, and defining the best location for the CCP in your production line ensures that the installation of the quality control system will be effortless and successful.

What to Do After the CCP is Installed?

Once the CCP is installed according to the HACCP plan, it is important to pay attention to the monitoring, record-keeping, and corrective actions:

- Monitoring procedures measure the critical limits at each CCP and should describe how and when the limits are measured, who is responsible for them, and how frequently they are measured during the production.

- Record-keeping is an important part of a HACCP plan. It is meant to store the data and provides a good way for food producers to prove that the food was produced safely and according to the set plan.

- Corrective actions should be established in case of the critical limits set in the HACCP plan are triggered, i.e. a detected foreign object in the food production. These actions usually include the identification of the problem (how did the foreign object get into the production) and the steps taken to assure that the problem will not occur again.

Conclusion of foreign object detection in food production

In conclusion, the HACCP plan and the foreign object detection requirements often trigger the implementation of a quality control system in food production plants. However, it is not an isolated process, and instead becomes a seamless part of the complete production process. This results in higher productivity levels, and it also provides food of a consistently high quality for you consumers.

If an X-ray system is used as the Critical Control Point, food producers get more value from their investment. The X-ray provides features towards a total food quality control that goes beyond inspecting only metallic foreign objects from the production. The complete quality of food products consists of multiple factors such as detecting also non-metallic contaminants, missing products, fill levels, the presence of components in the product, product counting, and reporting, etc. This broadness of capabilities is one of the main reasons why the X-ray systems are becoming more and more popular choices as Critical Control Points for food factories worldwide.

we want to help you

INTERESTED TO HEAR MORE ABOUT X-RAY INSPECTION SOLUTIONS?

Contact us or read more about the most important factors that food manufacturers should take into consideration when investing in inspection equipment.

Download our free white paper by clicking the button below and learn more!

Download free white paperWant to learn more about Mekitec x-ray inspection systems?

Click the link below and familiarize yourself with our solutions!

Learn More About X-Ray Systems