Selecting the right

Inspection solution

For your food products

Selecting the Right Product Inspection Solution for Your Food Products

There is a fair amount of options for food safety and quality inspection, and food manufacturers might find it challenging to choose the right inspection solution that fits their needs.

The most important thing for a food manufacturer is to have a clear understanding of their specific production process and its lacks or needs. This helps tremendously when evaluating the different inspection solutions. The HACCP (Hazard Analysis & Critical Control Points) framework can help manufacturers to determine their needs.

Physical Contaminant Detection

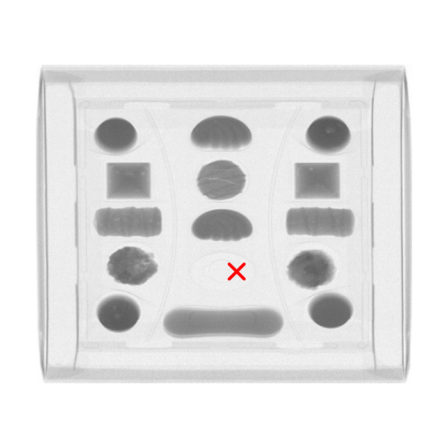

Detection capabilities are usually the first criterion for selecting the inspection solution. The inspection system should be able to detect unwanted quality defects or the physical contaminations identified in the HACCP plan without the risk of false rejection of conforming products or the non-conforming ones to remain in the production process.

Physical contaminant detection can be the first thing that drives food manufacturers to implement new or better inspection solutions, and the need for contaminant detection can come from actual physical contamination that needs to be resolved quickly or from a food safety standard that the food manufacturer wants to achieve. In either case, it’s crucial to identify the risks and have a plan for corrective actions. The internationally recognized HACCP framework and its principles help to determine the critical limits for physical contaminations that pose a safety risk if ingested.

There are many key factors that affect the detection capabilities of different inspection methods, such as the product itself, the packaging material, or the physical characteristics of the foreign contaminant. One important factor is the placement of the Critical Control Point. In our previous blog, we explained the seven reasons why food manufacturers should inspect primary packaged products; you can read it here.

Limitations in Different Inspection Technologies

All inspection technologies have their own limitations in detection capabilities. For example, metal detector systems cannot inspect products that are in metalized packaging whether it is an aluminum box or metal film wrapping.

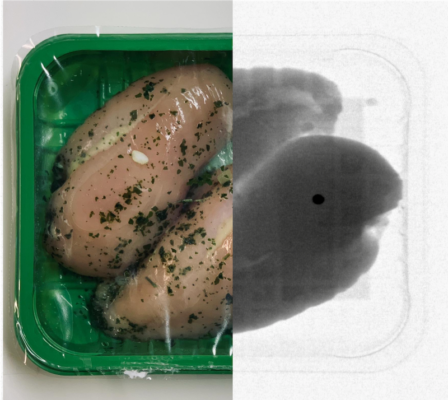

X-ray inspection’s limitations are directly related to the density variations between product and the contaminant, that’s why detecting very low-density objects, e.g. hair or insects isn’t possible with any X-ray system.

And even though optical vision systems might be able to detect low-density contaminants, it’s only possible if the contaminant happens to be on top of the product.

To further investigate the detection capabilities of different inspection methods on your specific food products and contaminants identified in the HACCP plan, it’s necessary to conduct a thorough Application Test.

Achieve Overall Quality Control and Traceability

Another important reason to implement better inspection is the desire to achieve overall food quality control. This means that the food producer wants to further inspect and ensure the quality of their products and packaging.

Modern inspection solutions, such as X-ray, can help food manufacturers to achieve their goal of complete quality control by identifying missing, misshapen, or broken products simultaneously with physical contaminant detection.

X-ray technology also enables the enhancing of the production and supply chain traceability by offering reporting tools and the possibility to save each product image inside each production batch. In the case of a product recall, this is extremely beneficial as the food manufacturer is able to effectively recall only the defected batch, or prove that the contamination didn’t actually happen in their facilities.

These features help manufacturers to comply with various food safety certifications and standards and also protect the brand by delivering only the top-quality products to the customer.

How to Choose the Right Inspection Solution?

All available inspection technologies are quite different from each other, and each of them has their own advantages based and depending on food manufacturers’ needs. In some cases, the most successful inspection solution is to implement two different technologies (e.g. metal detection and X-ray inspection) at different phases in the food production process.

As with any other significant decision, it is wise to seek guidance from food safety professionals, who can help manufacturers to identify their needs and goals for product inspection.

Book free consultation

free e-book

Take your CCPs to the next level

Download the free eBook How to Get the Best Value from a CCP in Food Production and get the latest tips straight to your inbox!

In the eBook, we explain how to successfully implement an inspection system into your food production to ensure only the safest and highest quality products are delivered to your customers. The eBook explains what is expected from a CCP now and in the future, and why you too should inspect primary packaged products.

Explore our references